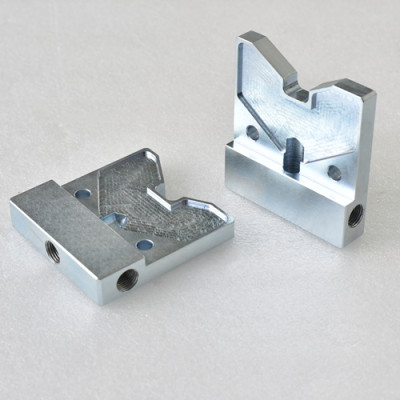

Black dyeing surface treatment after precision parts machining

Black dyeing surface treatment after precision parts machining

| Categories | Surface treatments & coatings |

|---|---|

| Brand | ZK Precision CNC Machining Manufacturer |

| material | S45C/SS400/NAK55/SKD11/, etc. |

| Heat treatment | There is no |

| Surface treatment | There is no |

| FOB port | Dalian port |

| Terms of Payment | T/T |

| Update Time | Mar 14,2025 |

Main business |

Our main businesses include Metal Fabrication,

Sheet Metal Fabrication, Custom Metal Fabrication, Machine Parts, Spare Parts

Cast, Welding Parts, Injection Molded Parts, Custom Sheet Metal Fabrication and

3D Printed MetalMold parts, precision metal fabrication, precision metal

fabricating, precision mold parts, ceramic molded parts, CNC machining milling

parts, custom aluminum parts, precision metal fabrication, precision mold

parts, precision metal fabrication, precision mold parts, precision metal fabrication,

precision mold parts, ceramic molded parts, CNC machiningSheet Metal

Fabrication, Custom Metal Fabrication, etc |

||

Materials |

Aluminum Alloy : A5052/A6061/A6063/A7075/A2017/A2014/etc Brass Alloy : 3602/2604/h59/h62/Bc/c3604/BsB/C1100/C1020/C1220/etc Stainless Steel Alloy : 303/304/316/310S/412/etc Steel Alloy : Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/POM/PEEK/PC/PV/etc We handle many other type of materials. Please contact us if your required material is not liste |

||

Surface Treatment |

Blackening, polishing, anodizing, chromium

plating, zinc plating, nickel plating, coloring, salt bath nitriding, gas

nitriding, TiN layer, titanium plating, etc |

||

Heat treatment |

Vacuum quenching, quenching tempering, flame quenching, carburizing quenching, high frequency quenching, etc |

||

Testing equipment | CMM、Tool microscope、multi-joint arm、Automatic height gauge、Manual height gauge、Dial gauge、Marble platform、Roughness measurement、Ultrasonic hardness tester、all kinds of bar gauge、 thread gauge and other testing tools. | ||

Processing equipment | Zhongken Machinery has DMG 5-axis machining center, turning and milling compound machine, optical grinding machine and other advanced processing equipment, and a number of three axis machining center, CNC lathe, grinding machine, milling machine, Sadik wire cutting, EDM machine, cylindrical grinding machine and other dozens of processing equipment. | ||

File Formats | Solid Works,Pro/Engineer, UG,AutoCAD(DXF,DWG), PDF,TIF etc. | ||

Packing | 1. Industrial packaging

plastic tube+carton +wooden case2. Commercial packing plastic bag+ box+carton+wooden pallets 3. As the clients' requirement | ||

Deliver | 1. DHL、OCS、FEDEX、TNT、SF Or according to customers' requirement 2. Delivery Detail:Nomally ready goods and stock within 5-25 working days

3. It takes 3-5 days to get the goods to you by air、Generally, it takes 5-7 days for the goods to arrive at the port when they arrive in Southeast Asia | ||

Quality Assurance | ISO9001:2008 Certified.TUV

Zhongken machinery also won credit enterprises, quality enterprises, AAA enterprises and other honors | ||

Exported To | Japan, America, Canada, England and Belgium Germany, Russia, France, Italy, and all countries | ||

Welcome to Dalian Zhongken Machinery Co., Ltd | |||

- Loading...

- Aluminum CNC Machined Parts: Why Do You Need Them?Aluminum is one of the most successful commercial metals in human history. The material has been used to make durable and lightweight parts in industries such as aerospace, military and defense, and other industries. This article discusses some interesting things about aluminum CNC machined parts.

- What Should I Do if the Aluminum Parts Are Easily Deformed During CNC Machining?There are many reasons for the deformation of aluminum alloy parts, so in the process of processing, measures to reduce the deformation are particularly important. The following article talks about some measures to prevent the easy deformation of aluminum parts during CNC machining.

- *Name

- *Tel

- *Title

- *Content