ZK ZK Precision Grinding Service

Home / ZK Precision Grinding Service

ZK Precision Grinding Service

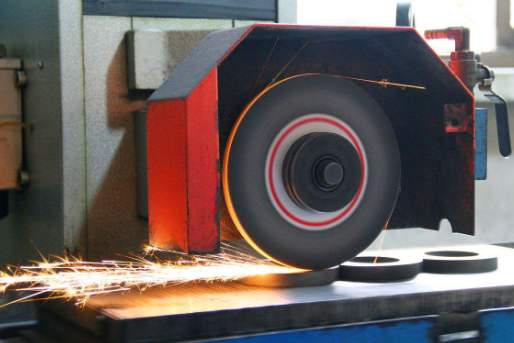

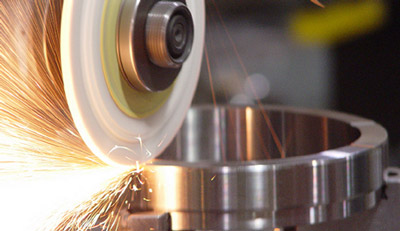

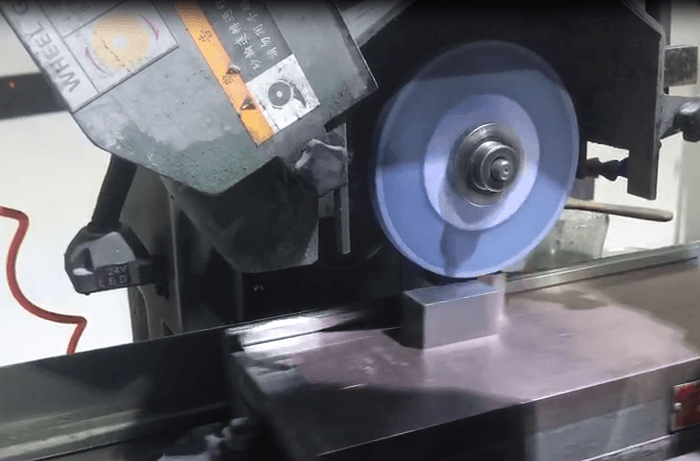

Like our other machining operations, we specialize in complex machined parts, you can enjoy precision grinding services for high demanding projects.We have advanced Multiple Hand-Operated Grinder, Flat Grinder, CNC Grinder and Optical Curve Grinder to finish ID/OD Grinding and JIG/Surface Grinding, can grind not only cylindrical parts but also unique shapes and partial diameters. For Jig/Surface Grinding, Our CNC and manual jig equipment lets us grind holes and complex forms to very precise tolerances, and also can grinds high tolerance parts to a mirror-like surface finish, while meeting flatness, parallelism, and squareness requirements.Frequently updated grinding equipment and careful adherence to quality standards offer our customers the comprehensive service for projects ranging from large and simple to small and complex.

Precision Grinding Capabilities

Our grinding systems that can achieve surface finishes to 0.2~0.025 Ra with tolerances as tight as 0.002mm. Detailed tolerance and surface finishes can vary due to material type of both the part and the grinding wheel.Min ID Grinding diameter : 6.0mmMax OD Grinding diameter :260mmMax Surface Grinding Size: 1000mm

CNC Grinding Material

stocks a variety of wheels for grinding most rigid materials including most metals: Aluminum, Stainless Steel, Copper, Steel, Brass, Titanium, Sterling Silver, Bronze, and Graphite etc.

Application

CNC grinding services are essential in offering a comprehensive machining solution for automotive, commercial, medical, aerospace and military products and components.

Custom Machining Service as Your design, without MOQ.

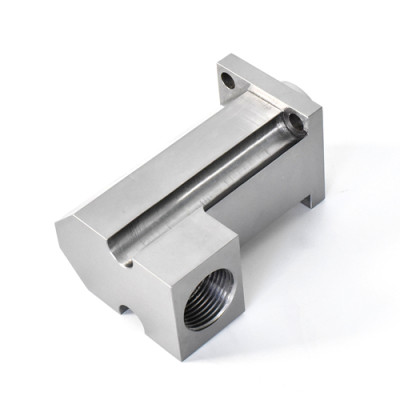

Our Grinding Parts

What's Your Next Move?

Navigation

News

- Dalian Zhongken Machiney to Exhibit at M-Tech Osaka 2025We are pleased to announce that from October 1 to October 3, 2025, we will participate in the 28thM-Tech Osaka. Our booth is located at Hall 6, B Zone, Booth 54-6. Looking forward to meeting you in Osaka!

- Aluminum CNC Machined Parts: Why Do You Need Them?Aluminum is one of the most successful commercial metals in human history. The material has been used to make durable and lightweight parts in industries such as aerospace, military and defense, and other industries. This article discusses some interesting things about aluminum CNC machined parts.

Request a quote

- *Name

- *Mobile Phone

- *Title

- *Content