What are the Advantages of Precision Engineering?

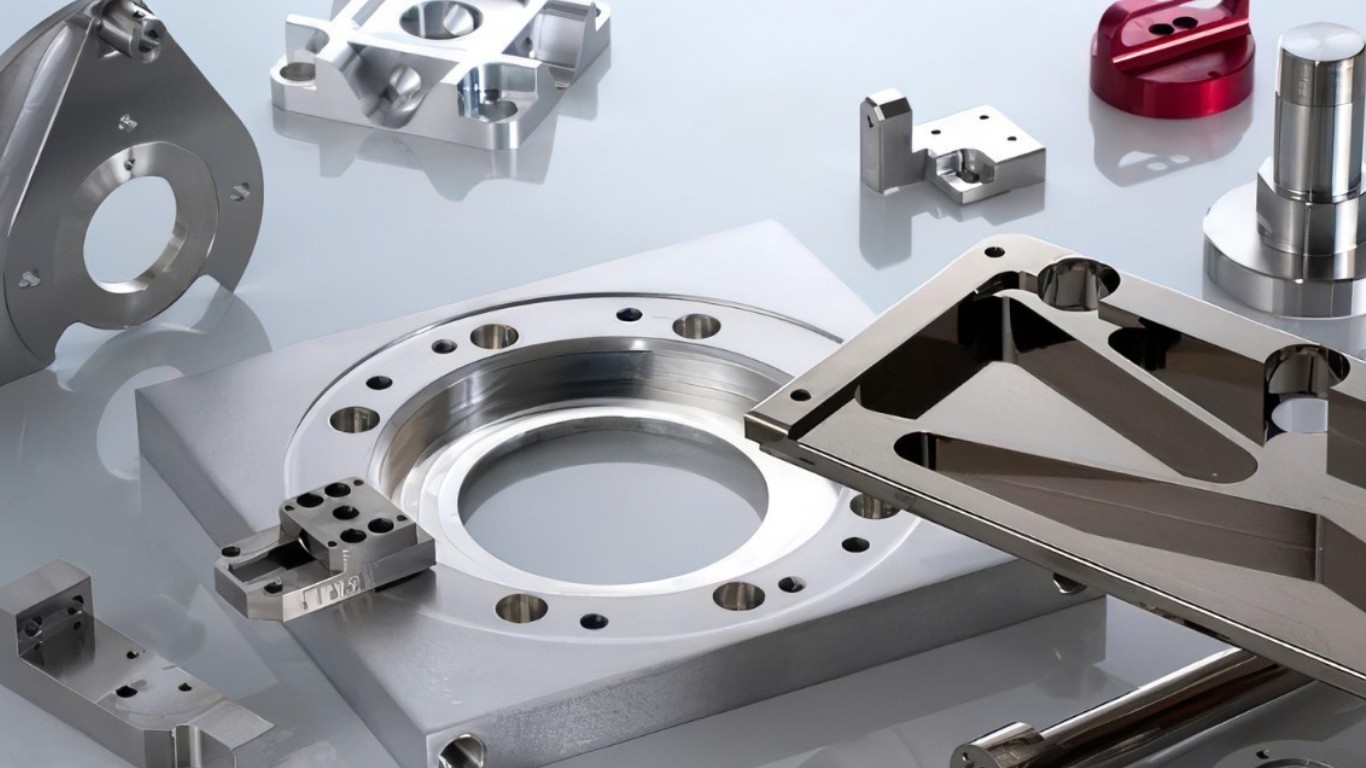

Precision engineering has transformed modern manufacturing. It enables us to manufacture complex, high-spec parts with an exceptional level of precision and detail, and mass-produce them for different applications in many different fields. Such high precision can only be achieved by CNC machining. It offers a range of distinct advantages over hand-made. So let's take a look at how these advantages can benefit you.

Powerful and running smoothly

Precision mechanical parts serve their purpose well. They are designed to fit and work together smoothly and seamlessly. This reduces noise and friction.

Durability

Less friction means precision parts are less prone to wear. They can run longer while maintaining the same high functionality and are less prone to failure and downtime.

Low operating costs

Precision-manufactured parts are designed to run more efficiently, using less energy. They can run for longer intervals without maintenance. And they don't wear out quickly, so you don't need to replace them as often.

High safety and reliability

Precise mechanisms operate more reliably and require less manual intervention for maintenance and adjustment. This eliminates most of the potential for human error. Many sophisticated machines also have self-monitoring capabilities, so they can alert you to problems early, long before they become dangerous.

Accurate measurement, evaluation, and reporting

The more sophisticated the equipment, the more accurate the results. This is especially important in the medical field, where accuracy is critical for diagnosing, delivering the right amount of treatment, and saving lives.

Water/airtightness

Precision-engineered components fit together perfectly. This is essential where the system transports liquids and gases. Precision parts ensure adequate and consistent flow. They also prevent inefficient and wasteful leaks.

Easy access and maintenance

Every facility needs easy access to maintenance, replacement, and repair. With precision machined parts, it can be easily engineered into the design.

Comply with industry standards

Zhongken has passed BVR certification and ISO 9001 quality management system certification. These certifications are critical to building customer confidence and reassuring you that we can deliver the high-spec precision parts you need.

As a Chinese custom CNC machining parts manufacturer, ZHONGKEN has been committed to precision mechanical parts processing, mold parts processing, casting, sheet metal parts processing, and export since its establishment. Our products can be used in semiconductor equipment, packaging machines, printers, packaging equipment, auto parts, medical equipment, food machinery, automation equipment, etc. Please contact us if needed.